Joysticks

For industrial and medical applications

Guide for Joysticks

Index

- Applications for joysticks - the right choice of design

- Axis configuration - the selection of the available degrees of freedom

- Axis configuration - choosing the right limiter

- The handle - the interface to the user

- Sensor technologies - contactless, potentiometric or by switch?

- Reset characteristics and haptics - feedback and control feeling

- Outputs and interfaces - analogue or digital?

- Tips and hints:

- Product customizations

Applications for joysticks - the right design choice

To determine the best joystick for your application, the first step is to select the size. In most cases this will narrow down the range of products. The designs of the various joysticks can be divided into the following categories: Thumb, Finger, Hand and Desktop. As each of these has been designed for fundamentally different applications, choosing the right type is usually straightforward.

Thumb joysticks are the smallest type

A classic application is remote controls, where an operator has to hold a housing in place, leaving his hand free for the input movement. The control is therefore typically done with the thumb. Thumb joysticks are also installed in control panels or in large handheld joysticks because space is often limited and the dimensions of thumb joysticks are not much larger than those of buttons and switches.

Finger joysticks are the all-rounders in the medium-size range

These joysticks provide the user with the highest level of operating precision due to the fact that the human fingers or fingertips can exercise the best control when operating the handle. The applications are many and varied, and so is the variety of finger joysticks. This type of joystick is particularly suitable for controlling medical equipment, surveillance cameras or mobile machinery.

Hand joysticks represent the largest type

In general, mechanical stability increases with size. However, the application also places higher demands on the product. In the heavy-duty sector, for example, joysticks are used to control cranes, construction machinery and other large vehicles and equipment. Safety requirements are particularly high, and redundant electronics and sensors are usually required. As a result, investment costs increase with the size of the joystick.

Desktop joysticks represent a special group

As a rule, these are integrated finger joysticks in desktop housings, which usually with a few buttons for additional functions in the housing. These input devices cover the rather large demand for stationary applications with already permanently installed finger joysticks. The area of video surveillance is particularly worth mentioning. Nowadays only USB variants are of importance here, because the input information is usually transferred immediately to a computer.

Axis configuration

The selection of the available degrees of freedom

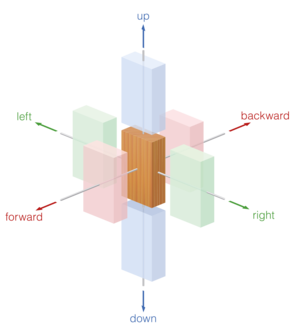

Each joystick model has certain limitations regarding the available number of degrees of freedom and the freedom of movement for operation. The degrees of freedom are called axes for joysticks. Most models offer 2 axes, i.e. the handle can move in X and Y directions (forward/backward, left/right). On some models, the handle can also be rotated. This is called the Z-axis and allows the input of a total of 3 degrees of freedom in simple designs.

Most thumb joysticks offer a maximum of 2 degrees of freedom. Many finger joysticks are available as 3-axis joysticks. However, even more axes can be implemented for hand joysticks. In the head plate of these joysticks there is space for a lot of input elements and thus for additional degrees of freedom.

An exception to the range is our SpaceMouse® Module: here the control handle can be deflected in all three directions - in addition, tilting/rotation of each direction is possible. This results in a total of 6 degrees of freedom, allowing direct, intuitive navigation and control in 3-dimensional space.

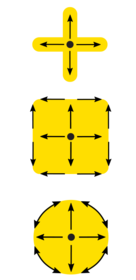

Axis configuration - limiter selection

The freedom of movement of the main axes can be restricted in almost all models. In some applications, when the first axis deflects, the second axis should be blocked ("plus" limiter). In other cases the simultaneous deflection should be possible only to a reduced extent (round limiter). The square limiter offers full freedom of movement. Some hand joystick models offer the possibility of locking in the middle or at deflection. For this, see the section "Reset characteristics and haptics".

The handle - interface to the user

The configurability of the handles increases with the size of the model. Thumb joysticks offer many handle shapes and a few offer the possibility to switch with pressure on the handle.

With finger joysticks, the variety increases further and several push buttons are already possible.

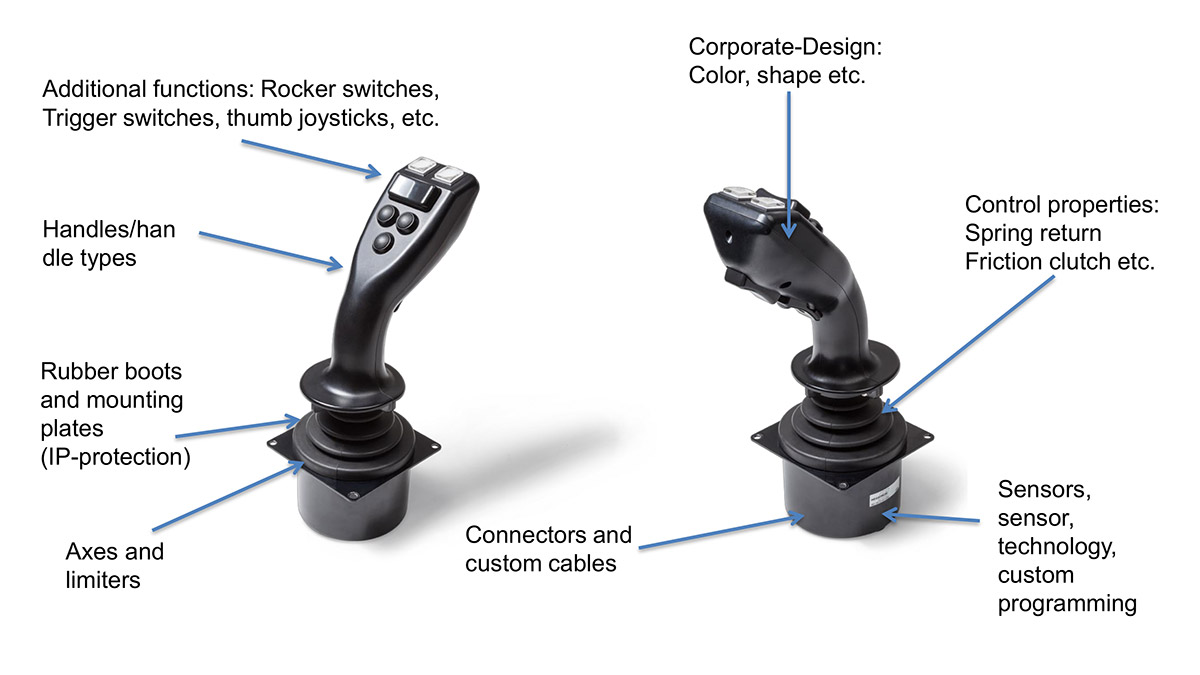

Hand joysticks offer the largest variety of handle options. In fact, almost all models are customized for the application. The configurability is usually higher than indicated on the data sheets. Feel free to contact us to get the best solution for your application!

Selection of sensor technology

Contactless, potentiometric or by switch?

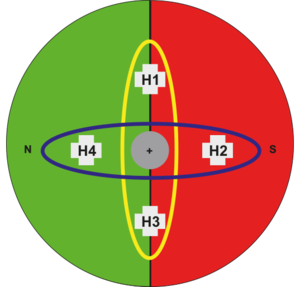

Two technologies are of importance for industrial joysticks today: Hall sensors and potentiometric sensors.

Hall sensor technology is a contactless technology in which the sensor detection of the deflection is contactless. This has the advantage that there is practically no wear and tear and therefore no change in sensor behaviour over the entire running time.

If there are no particular reasons for excluding this technology, such as strong electromagnetic interference in the application environment, Hall sensors are usually chosen.

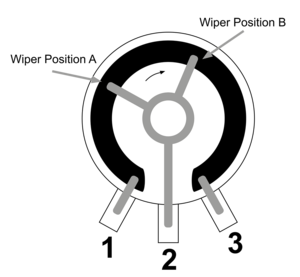

Potentiometric sensors use wiper and resistance elements for sensory detection. Only high-quality, so-called precision potentiometers meet the most demanding requirements for quality and lifespan. The advantage of this technology lies in its insensitivity to external interference fields. Joysticks with potentiometric sensors are particularly popular in medical technology, where the requirements for immunity to X-rays, other interference fields and electrostatic discharges are very high.

If a continuous output signal between minimum and maximum deflection is not required in applications, switch sticks are a good choice. These are only equipped with switches that detect the deflection of the joystick. Thanks to their simple and straightforward design, switches are very insensitive to interference and disturbances. However, the number of switching operations is limited and usually results in a shorter lifespan. A special situation is the use of switch sticks for switching high currents directly via the joystick, which otherwise has to be done with an external relay.

In general, it should be noted that the sensor technology used does not say anything about the quality and durability of the joystick's mechanics. It can happen that the mechanics of low-cost components fail long before the sensors, so the sensor technology should not be overrated. In uncomplicated cases we recommend compact Hall joysticks, as these are the easiest to integrate today and are suitable for most applications.

Safety-critical applications often require redundant designs with two sensor elements per axis. Almost all of our models are optionally available as redundant versions.

Return mechanism and haptics

As a rule, the application determines whether the joystick should return to its initial position when not actuated (by spring return) or whether it should remain in the last position in one or more deflection directions (friction brake, optionally also by detent positions).

Most modern joystick models are equipped with a central spring. This spring returns the operating lever to the middle position for both deflection directions. The strength of the spring can be adjusted. For constructive reasons, no further adjustments such as an additional friction brake can be implemented.

If the application requires friction brakes or detent positions, special models must be used, whose design is larger and more complex, but which are therefore more flexible for such adaptations.

Outputs and interfaces - analogue or digital?

Almost all joystick models offer analogue voltage outputs in the range of 0-5 V. These are usually the basic versions of the products and accordingly the most economical versions. Since potentiometers are basically passive components, joysticks with potentiometric features usually only offer analogue outputs. For some models only analogue versions are available, which are sufficient for most applications. Modern models with non-contact sensors offer additional digital interfaces, such as pulse width modulation (PWM), USB, RS232 (serial) and CAN bus variants. The interfaces offered are very different and are only listed for certain series. Therefore, it pays off to look only at these products when an interface is specified.

Tips and hints

Circuit

Depending on the sensor technology used, the evaluation electronics must be designed very differently. Hall-effect joysticks use integrated circuits as sensor elements, which are installed on printed circuit boards within the housing of the joysticks. Depending on the circuit board design, different operating parameters must therefore be observed, which can be found on the data sheet. This therefore also applies in general to the bus systems offered.

In potentiometric models with analogue outputs, however, the angle sensors are passive components (conductive plastic potentiometers) and the models are usually not equipped with control electronics. The connections lead directly to the potentiometers, which must be operated in a voltage divider circuit in order not to damage the sensors. Please take special care that no relevant current flows through the outputs, as this could damage the potentiometer wipers.

Environmental influences

Vibrations, mechanical overload, heat, aggressive substances, etc. can endanger the operational safety of input elements. The resistance of the individual models varies greatly and generally higher prices are justified by higher resistance or by better technical specifications.

In general: The specified protection classes are indicated above the panel. If moisture is expected below the seal, products that allow optional sealing of the electronics must be selected. Please contact us if you have this requirement.

The specified operating temperatures are used as reference values for the recovery properties of the mechanics and for the elastomers used for the sealings, but also for the electronic components. Most joysticks also function at lower temperatures than those specified in the data sheet. Especially for safety-relevant applications we advise against operating the joysticks outside these limits.

Mounting

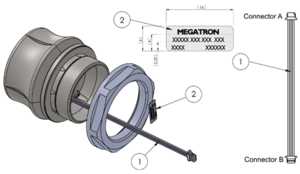

Most models can be mounted into a panel from above. Typically, the base, the joystick pot, is round and is fixed by 4 screws. On some models, the handle fits through the recess in the panel and can therefore also be installed in the panel from below. Depending on the degree of protection and the general type of construction, the covers of the mechanics (rubber bellows) are either screwed together with a cover ring to form a seal or separate seals are supplied to ensure the seal in the panel.

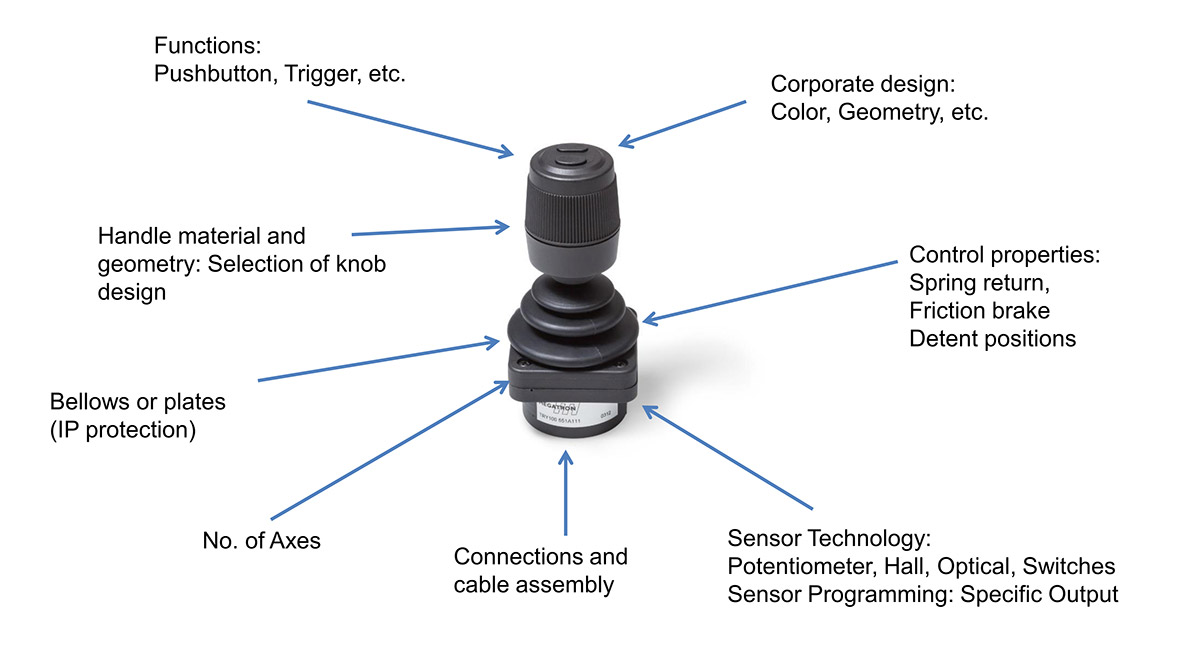

Product customizations

We at MEGATRON have decades of experience as a reliable partner for industrial and medical technology customers. Our particular strength is the customization of products. Especially the optimal adaptation of our joysticks to the application is in demand for small to medium quantities, as niche markets are often served here.

Joysticks offer a variety of customization options. Depending on the feature that is to be modified, these adaptations can already be carried out for small quantities. Please contact us and describe your request - we will find the best solution for your application.

Modern industrial joysticks are mostly modular systems. This enables relatively cost-effective adaptation of the joystick to the application, since individual components can be easily exchanged during assembly. The availability of the components depends on market requirements and defines what is a standard or a special variant. Thanks to the modular system, the effort required for customer-specific special designs is kept within limits, as only individual modules need to be adapted or redesigned.

One thing that modular systems and joysticks with many variants have in common is that the abundance of options makes it practically impossible to represent every possible electrical and mechanical combination or even to stock it as a physical article. This is because the total number of all products that can be generated by the order key results multiplicatively from the choices for each module of the construction kit. Particularly in the case of highly customizable product series with many options, the article diversity amounts to several hundred to a thousand variants that result from the combinatorics of the order code. For this reason, we have highlighted those product options in the data sheet for some series that have a high level of acceptance on the market and declared them as standard.

The selection options of the joystick features are electrical or mechanical adaptations. In addition, we realize product customizations that go beyond the options in the order code and give examples of other possibilities. It is the ability to optimize the offer to the requirements of the application that distinguishes us.

The prerequisite for this is to know the application and the field of application as well as possible. Only in this way can we analyse the product you are requesting in terms of its technical possibilities as well as its economic implementation. Within the scope of our consulting, we determine the best product with regard to your application requirements and, if necessary, suggest alternative products if they offer advantages for you from an economic as well as a technical point of view.

Mechanical and electrical optimizations

Cable and connector assembly

Save time and effort by receiving your product already with its final cable confection, suitable for integration in your production line without additional effort from your side. Please tell us the requirements regarding environmental conditions and installation situation - on request, we will take over the preparation of the technical documentation, the operational procurement and the implementation for the assembly of cables and connectors for the offered part.

Optimization of the handle design

A wide selection of knob variants is available for our joystick series to optimize the feel of your application. But we also implement an adaptation of the handle shape according to the customer's wishes. On request, we will prepare design proposals and procure all the necessary components to realize the ideal product for your application.

Custom programming

Hall joysticks and models with optical sensor systems in particular use modern programmable integrated circuits (ICs) with which the signal behaviour of the joystick can be optimized for the application: for example, the response behaviour when deflected from the centre position (dead zone, see illustration) or the change of the signal span at the output. We analyse the technical conditions under which special programming is possible in series production and produce prototypes for your application. Depending on the possibilities, the joysticks are reprogrammed during the production line or separately with specially created production equipment.

Adaptation of colour and shape

As a control element, the joystick interface is very often in the central field of vision of the application. Therefore, the recognition value is of high importance. We take over the corresponding corporate design according to your specifications. Using 3D printers, printed prototypes can be produced promptly for sampling and the ideal shape can be found in a relatively short time. With a corresponding number of pieces, the design can be realized cost-effectively by injection moulding.

Customization of haptics and operating feel

The operating feel in the application is significantly influenced by the shape and material of the handle, but above all by the force required for deflection. A high return-to-centre force, for example, can lead to faster operator fatigue than a low restoring force. However, a relatively high restoring force usually supports precise control of the machine. As always, the right choice depends on the requirements of the application and as long as the design of the joystick allows for an adjustment of the spring, it is a manageable effort. Simply contact us to find out about the possibilities with the joystick model you favour.

Customization of input elements

Another common customization is the optimal attachment of additional functions in the handle of the joysticks. Numerous joysticks already offer a wide range of choice. Basically, the number of elements to be accommodated is limited by the possible space in the knob and the number of electrical cables to be routed into the base. Together with you, we determine the possibilities according to your requirements and, if necessary, produce customized designs in order to implement the required operating functions in the best possible way.

Joysticks play a central role as input devices in operating concepts at the interface between man and machine. They are used in many industrial applications, such as robotics, cranes, agricultural and forestry machinery, construction machinery, medical technology, as well as for controlling mobile machines and industrial production lines. Due to the often harsh environmental conditions, an industrial joystick must be robust and have a long service life to minimize failures.

The joysticks offered by MEGATRON use modern non-contact Hall sensors or high-quality potentiometers. Our industrial joysticks are characterized in particular by their high-quality components and construction, which guarantee a long-lasting and reliable function. MEGATRON offers the right solutions for this wide range of applications and their different joystick requirements.

Thumb joysticks for portable devices or panel integration, finger joysticks for sensitive control tasks, hand joysticks for use in the harshest environments and joysticks in ergonomic desktop housings with integrated buttons for additional functions. This enables us to meet a wide range of customer requirements, while at the same time offering customized solutions through our in-house development, production and quality assurance.

EN

EN DE

DE ES

ES FR

FR IT

IT