Rotary Potentiometers

For precise setpoint setting by hand

Guide Rotary Potentiometers

Index

Basic questions about potentiometers? Here you will find the answers

What is a rotary potentiometer?

This guide deals with potentiometers as input devices in the HMI function. General information on potentiometers as actual value transmitters, click here.

In rotary potentiometers, rotation changes the electrical resistance on the resistive track and a wiper picks up the voltage potential on this track. They usually have three electrical connections and a shaft for mechanical coupling of the rotary knob. They may have special features such as integrated end stops or a slipping clutch. The practical possibility of adapting the rotation inhibition of the shaft to the requirements of the application underlines their use as an interface between man and machine.

Adaptation of the operating torque

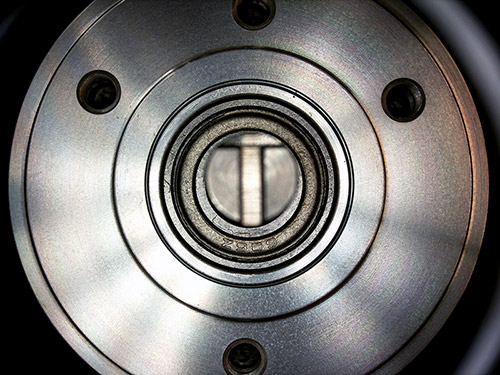

Ball bearing with shaft

In order for a potentiometer shaft to rotate, a certain amount of torque, the breakaway torque, is required to overcome static friction. Once the static friction has been overcome, the actuating torque must be applied to maintain the movement. In practice, only the actuating torque is usually specified in the data sheet and the term "operating torque" is used in common parlance. The breakaway torque is negligible in most cases.

The operating torque is determined at room temperature (approx. 20 °C) and is expressed in Newton metres, e.g. 5 Nmm. This value is achieved by the interaction of several components. For example, the type of shaft bearing and/or the use of grease. These two components, together with others, offer a wide range of possibilities to match the operating torque to the application.

Special greases can be added to meet temperature range requirements, to prevent unintentional adjustment or to provide a pleasant feel. The latter also has a significant influence on the choice of knob to be used. If a large diameter knob is used, the user will need less force to generate the required torque due to the leverage effect. Changing the default value can therefore provide benefits by adapting the operating torque to the application. We will be pleased to assist you with selection and any necessary adjustments.

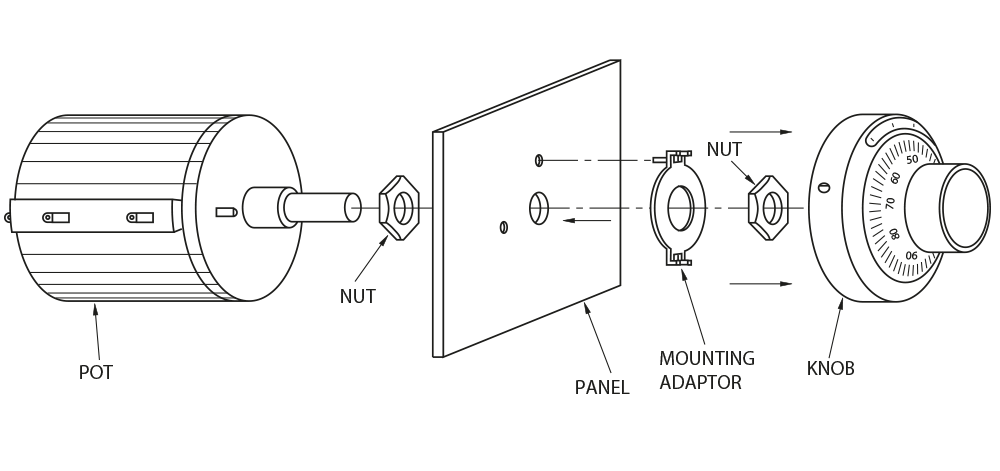

Mounting instructions for rotary potentiometer

Please follow the panel mounting instructions given in the datasheet, as well as the tightening torques and dimensions for threads and screws. Potentiometers with bushes in particular can have a negative effect on the haptics if not mounted correctly. It is not recommended to deliberately increase the operating torque by assembly. On the one hand, the inhibition cannot be guaranteed permanently and on the other hand, it can influence the function of the potentiometer.

Example

Single or multiturn rotary potentiometer?

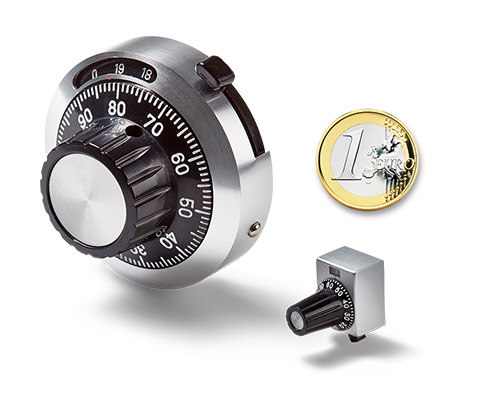

Knobs compared with one Euro

The accuracy, repeatability and speed of adjustment will depend on the application. A maximum of 360° can be covered with a single-turn potentiometer and 3600° with a 10-turn potentiometer.

Example: Your application requires a resolution of approximately 5° per step, and you want to achieve this with a single-turn potentiometer of 350°.

In practice, it depends on the size of the control knob and how fast or how large the path for an adjustment should be. With a relatively small knob, it is difficult to achieve safe and precise manual operation in our example. You would need to be able to adjust about 70 positions in one turn with very small movements. A relatively large knob would be more suitable for comfortable operation.

A multi-turn potentiometer might be more suitable for this example, assuming a small knob. A multiturn with e.g. 3600° offers much more comfortable handling for safe, accurate and repeatable operation. However, further travel or several turns are required to set a required value. If quick manual adjustment is required, a single-turn potentiometer has an advantage over a multi-turn potentiometer.

In summary, the following can be said: A single-turn potentiometer is more suitable than a multi-turn potentiometer for quick and coarse adjustments. With the latter, it is possible to create much finer and more precise control concepts, while at the same time requiring repeatability. The choice of control knob also has a decisive influence on the ease of adjustment in practice.

General tips about rotary potentiometers

Typically, rotary potentiometers are panel mounted into a housing. We recommend the use of seals between the components if cleaning agents are used or if the application is for outdoor use. An additional shaft seal is recommended if the application is used at low temperatures. Otherwise, condensation may form on the resistive element and affect the signal. If further protection is required, potentiometers with sealed housings are available.

Particularly in battery-powered, mobile handheld applications, rotary potentiometers show their strengths in terms of power consumption. Only minimal power is required for operation. This technology is therefore virtually unrivalled for applications where low power consumption is required.

Our potentiometers almost exclusively provide a linear output signal. Exceptions are our sine/cosine potentiometers. Both are not suitable for audio applications as they do not have a logarithmic curve!

Completely pre-assembled sets

Our pre-assembled kits offer the advantage that the potentiometer and knob are matched to each other. The dimensions of the potentiometer shaft fit exactly into the knob mechanism, the torque is matched to the behaviour of the knob and a rubber gasket provides optimum protection for panel mounting. The knobs have a 3-digit roller for presetting or reading setpoints and the potentiometers are available in 3, 5 or 10-turn versions. For electrical integration, pre-assembled potentiometer/knob combinations are available with terminal connection or solder lugs.

Suitable rotary knobs for rotary potentiometers

In particular, the shaft geometry of the potentiometer is critical to the mounting of the knob. Please ensure that the shaft is dimensioned appropriately and take into account the thickness of the panel. Our knobs are designed for different shaft geometries. We will be pleased to assist you with the selection and adjustment process.

Rotary potentiometers can be "operated" by hand. They are used as a man-machine interface for precise setpoint adjustment. For practical use, the controls have mechanically integrated end stops that limit the rotary movement and prevent it from exceeding the resistance track. An optional slipping clutch protects the end stops from excessive stress.

Environmental requirements dictate the type of operation and often require product optimization. Of particular importance is the ability to adjust the operating torque to suit the application requirements, for example to prevent unintentional adjustment. In addition, the haptic properties can be influenced to a desired degree.

MEGATRON is your partner for product optimization. As part of our consultancy service, we work with you to define the optimum product for your "design in". Our aim is to provide each customer with the best functional and economic result. With high delivery reliability and guaranteed product quality, we focus on long-term partnerships and accompany you throughout the entire life cycle of your application.

EN

EN DE

DE ES

ES FR

FR PT

PT IT

IT