Multiturn Potentiometers

With wirewound or hybrid resistive element

Guide Multiturn Potentiometers

Index

What is a multiturn potentiometer?

In the case of a multi-turn potentiometer, it is mainly the number of full turns that is measured in angular degrees. A 10-turn potentiometer therefore has a measuring range of 10 x 360° = 3600°. Some multi-turn potentiometers can be realized with up to 30 turns / 10800° (series 46 / 46HDS). This is because the higher the angle of rotation of the potentiometer, the more accurate the setting can be. They are suitable for use as precise setpoint and feedback transmitters where accurate angle measurement with an analogue output signal is required.

A typical application is the measurement of linear travel converted into rotary motion by a spindle drive. Here the multi-turn potentiometer provides accurate feedback of the various axis positions, for example in the memory function of "first class" aircraft seats or in general drive engineering.

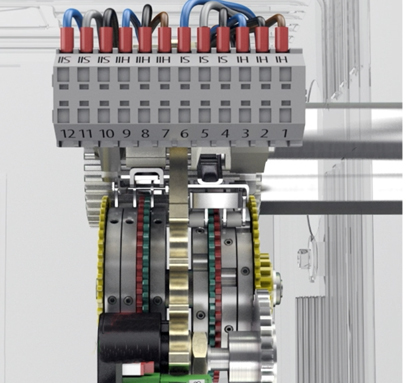

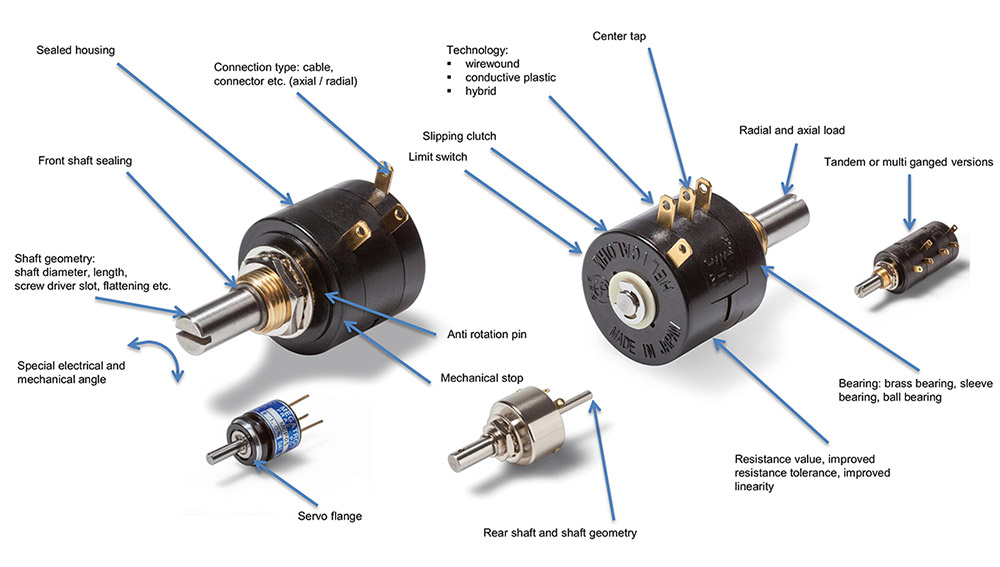

Note: Please do not confuse "multiturn" with "multiganged". Multiganged means that several potentiometers are connected in series via the potentiometer shaft to form a system. They are used in applications where redundant connections and/or galvanically isolated signals are required.

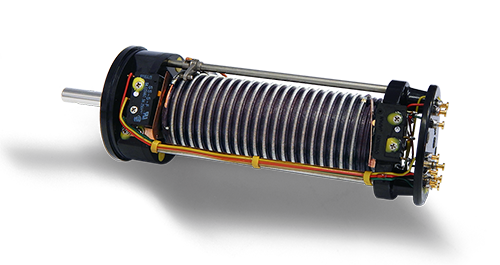

Design of multiturn potentiometers

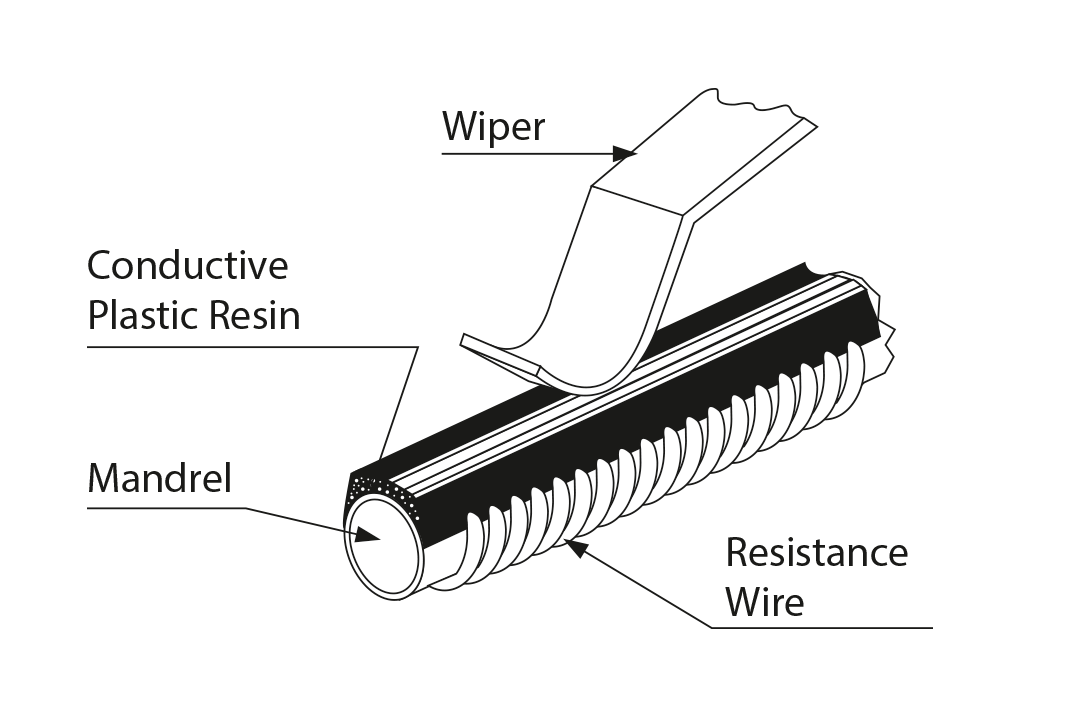

As with all potentiometers, a resistance track, a slider and connections are required. The slider picks up a voltage potential on the resistor track via the rotary movement and direction of rotation. The main difference between a multiturn potentiometer and a single-turn potentiometer (<360°) is the design and shape of the resistor track. The resistor track of multiturn potentiometers is spiral-shaped and allows the detection of angles ≥360°.

One turn is a full 360° rotation of the shaft and corresponds to one revolution of the spindle-shaped resistance track. More turns mean more possible rotations, more angular degrees and more space for the number of turns. This explains the longer housing for 5 to 10 turns or even more for up to 30 turns.

To prevent the slider from going beyond the ends of the spiral-shaped resistance path during a rotation, mechanical stops must be provided for the slider in both directions. To protect these stops from mechanical overload, integrated slip clutches are used as an option.

Multiturn Inner Design (wirewound)

Hybrid vs. wirewound element in comparison

Hybrid Resisitve Element

Both resistance elements are capable of detecting angles ≥360°. However, wirewound elements can cover much larger angles than hybrid elements. The latter are only available up to 10 turns (3600°), whereas wirewound multi-turn potentiometers can be ordered up to 30 turns, i.e. 10800°. The resistive elements also differ in their basic sensory characteristics:

The characteristics of potentiometers with a wirewound resistive element can be found here. Their main characteristics are very tight resistance tolerances and the ability to withstand higher electrical loads and low frequency vibration.

The resistive path of hybrid potentiometers is technologically the best, compared to the characteristics of conductive plastic potentiometers. Hybrid potentiometers are basically multi-turn potentiometers with the spiral resistance track covered with conductive plastic. Hybrid technology is therefore also characterized by almost infinite resolution, a very smooth output signal, high operating speed and long life, as is the case with single-turn conductive plastic potentiometers.

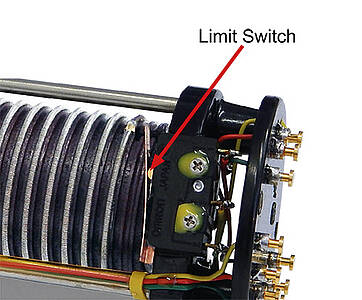

Multiturn potentiometers with limit switch

Limit switches are available on some models, which trigger a switching operation when a certain electrically effective angle of rotation is reached. The limit switches are factory configurable within the electrically effective angle of rotation or signal plateau. Life and maximum load are not the same for these switches as for the potentiometers themselves.

Tip for applications with exactly 360° (or slightly more)

A single-turn potentiometer with a linear signal curve is hardly capable of meeting a measuring range of exactly 360°. Therefore, multi-turn potentiometers are used for this task. If the application allows it, we recommend the use of a 3-turn potentiometer. On request, we can also supply 1-turn multi-turn potentiometers from the AL17/19 series, which meet the 360° requirement. Our sine/cosine potentiometers also meet the 360° requirement. However, they are fundamentally different in design and electrical characteristics from the multiturn potentiometers described here.

Product customizations

Frequently requested product adaptations include special resistance values, through-/rear shafts, centre taps, tighter linearity tolerances, shaft geometry adaptations, bushing or servo flange adaptations, or cable or connector assembly. Please do not hesitate to contact us for any assistance you may require.

Our multi-turn potentiometers cover angles up to 10800° (30 turns), enabling applications with measuring ranges ≥360°. They are available in wirewound and up to 10 turns in hybrid technology, the latter offering excellent signal smoothness, longer life and virtually infinite resolution. Redundant or galvanically isolated multi-turn potentiometers are available in tandem or multigang versions.

The larger the angle of rotation or the number of mechanical revolutions, the greater is the setting accuracy. Typically this kind of potentiometers is used in 3-, 5- and 10-turn versions, but there are also applications with a requirement for very large angular ranges, where 20- or even 30-turn versions are used. In addition, limit switches can be integrated, which can be configured at the factory within the electrically effective angle of rotation or signal plateau.

MEGATRON is your partner for the optimal product adjustment to your application. We are entitled to provide each customer individually with the best functional and economical result. With high delivery reliability and assured quality products, we focus on long-term partnerships and accompany you throughout the entire lifespan of your application.

EN

EN DE

DE ES

ES FR

FR PT

PT IT

IT