Conductive Plastic Potentiometers

Singleturn potentiometer with conductive plastic technology

Guide Conductive Plastic Potentiometers

Index

Resistance element and resolution

Conductive plastic potentiometers have a conductive plastic resistance element, from which the name for these potentiometers is derived. There is a conductive plastic layer on a carrier material. These layers are extremely smooth, mirror-like resistance tracks. In the application, these potentiometers provide a continuous signal without steps, have a quasi-infinite resolution and enable a very long lifespan of ≥50 million revolutions. Furthermore, conductive plastic potentiometers achieve excellent independent linearities of up to 0.02%. Conductive plastic potentiometers, which are manufactured in a "co-molded" production process, have an additional advantage: the adjacent connection transitions to the resistor track are manufactured very precisely, so that the wiper is much less worn when passing over the ends of the resistor track.

Conductive Plastic Element

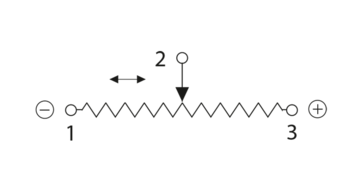

Circuit type

Conductive plastic potentiometers must never be used as variable resistors (rheostats), but only in voltage divider circuits. Otherwise, the resistor element will be damaged. Potentiometers generally show their strengths in voltage divider circuits. Temperature has hardly any influence on the output signal, because the tapped voltage at the slider or the electrical potential at the output remains largely unaffected here, since the divider ratio does not change.

Load capacity of the resistance element

| Example | Voltage U | Resistance R | Power P | Application possible? |

| 1 | 20 V | 1 kΩ | 0.4 Watt | yes |

| 2 | 30 V | 1 kΩ | 0.9 Watt | yes |

| 3 | 50 V | 1 kΩ | 2.5 Watt | no |

| 4 | 100 V | 5 kΩ | 2 Watt | no |

| 5 | 100 V | 10 kΩ | 1 Watt | yes |

Example MPA20/21 series

- available resistance values (0.5..100 kΩ) 1, 2, 5, 10, 50 kΩ

- max. load capacity 1 Watt

The following applies to power loss:

P = U² / R (power P = voltage U² / resistance R)

From this example, it is immediately clear that the 1 kΩ potentiometer cannot be used at an operating voltage of 50V. Otherwise, the load on the resistance element is too high. Please also consider the additional restrictions for the ambient temperature.

Please note that very high resistance conductive plastic versions will have a less favourable slider contact resistance, as this will also increase if the conductive plastic layer itself has a higher resistance.

Resistance elements in comparison

| Resistive element | Conductive Plastic | Wirewound | Hybrid |

| Lifespan | ++ | 0 | + |

| Signal quality / resolution | +++ | + | +++ |

| Linearity | +++ | ++ | ++ |

| Electrical travel | max. 360° | 10800° | max. 3600° |

| Operational speed | ++ | - | ++ |

| Max. wiper current | - | + | - |

| Shock / Vibration | - | -- | -- |

Legend: +++ best | ++ very good | + good | 0 OK | - low | -- unfavourable | --- not appropriate

Decision support

Choosing the right potentiometer technology depends on a number of factors. If your application requires long life and tight linearity tolerances, conductive plastic technology is a good choice for singleturn applications. Conductive plastic offers the longest life with up to 50 million shaft revolutions and the best linearity with up to 0.02% tolerance in very compact designs (e.g. MCP22). The very smooth resistive track and very low signal noise provide almost infinite resolution. In addition, the design allows adjustment speeds of up to 400 rpm.

Please note, however, that conductive plastic potentiometers are not available as helical multiturn potentiometers. Conductive plastic potentiometers must be connected in a voltage divider circuit and the wiper current must be limited to a minimum.

Comparison between conductive plastic and wirewound potentiometers

When comparing conductive plastic potentiometers with wirewound potentiometers, it is important to note that the tolerance of the total resistance of conductive plastic potentiometers is generally somewhat greater than that of wirewound potentiometers. As the application must always be in the voltage divider circuit, this tolerance is not relevant to the useful signal. However, if the power dissipation of an electrical circuit needs to be known exactly, this tolerance should be taken into account.

On the other hand, wirewound potentiometers "tolerate" slightly higher current values than conductive plastic potentiometers, have excellent resistance tolerance values and very good linearity values. However, the surface of the resistive element is somewhat rougher due to its design and generates noticeable small steps in the output signal. The resistance design also places greater stress on the wiper, which affects its lifetime, which in many cases is significantly lower than that of conductive plastic potentiometers.

Hybrid potentiometers are for multiturn tasks

If similar values of conductive plastic potentiometers are required for multiturn tasks ≥360°, they are found in our hybrid potentiometers. These have a wirewound resistor track coated with conductive plastic. This protects the wiper and also enables a smooth output signal, almost infinite resolution and higher adjustment speeds.

Conductive plastic potentiometers in tandem designs

Conductive plastic potentiometers can also be equipped like wirewound or hybrid potentiometers in tandem design. What you have to consider, you can find here.

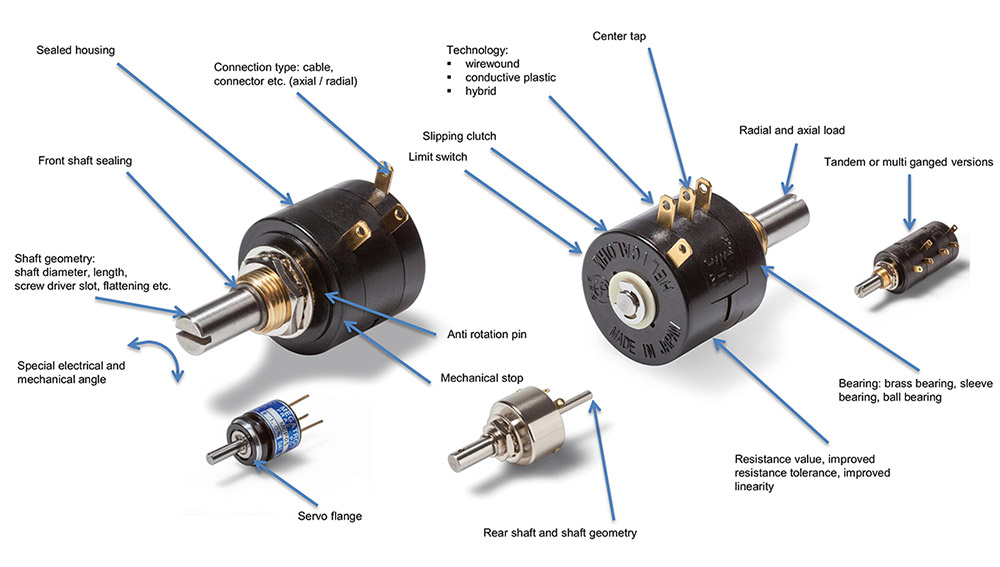

Product customizations

Conductive plastic potentiometers offer almost infinite resolution for angles up to max. 355° at max. 400 rpm due to the very smooth resistance track. They also offer the highest levels of durability and quality, providing an absolute analogue output signal with no steps.

In terms of design, the portfolio ranges from miniaturized, extremely compact conductive plastic potentiometers with a minimum installation depth of < 8 mm to fully sealed IP65 housings. However, there are applications that require additional technical product customization.

MEGATRON is your specialist in these matters. As part of our consultancy service, we will work with you to define the optimum product for your "design in". With high delivery reliability and assured quality products, we focus on long-term partnerships and accompany you throughout the entire life cycle of your application.

EN

EN DE

DE ES

ES FR

FR PT

PT IT

IT