Power Resistors

With wirewound or metal film technology

Guide Power Resistors

Index

What is a power resistor?

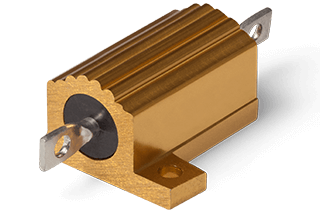

Power resistors belong to a special class of electrical resistors. Electrical resistors are electrically passive components that limit the current flow through an electrical circuit. The special main feature of power resistors is their suitability for use at high power, i.e. at very high loads and the resulting temperatures.Special attention must be paid to the maximum power consumption of the components due to power loss, caused by the heat generated during operation.

Power limits - the power derating curve

Electrical power is formed by multiplying current and voltage or by the ratio of the square of the voltage to the resistance value or by multiplying the square of the current by the resistance:

P = I*U = I²*R = U²/R

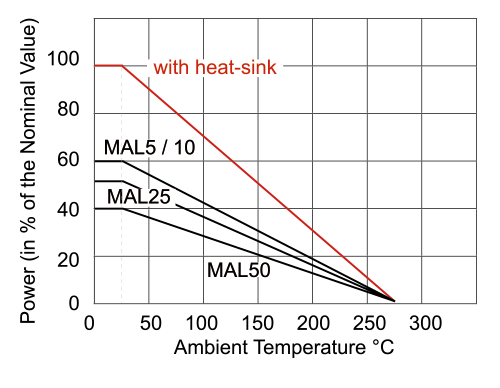

Therefore the electrical power follows a square function of current or voltage, i.e. an increase of current or voltage by, for example, 20% leads to a power increase of 44%. This regularity must be taken into account when selecting the component. In addition, the thermal transfer of heat loss must be enabled by the high power consumption. The heat dissipation is supported by the materials used for the resistor housings. These are often aluminium housings with additional heat dissipating cooling fins or housings made of heat dissipating ceramics. In addition, appropriately dimensioned heat sinks, usually in the form of aluminium plates, are used on which the resistor is mounted, if necessary together with a heat conducting paste. In the data sheets of power resistors there is usually a curve that shows the relationship between maximum permissible power and the ambient temperature, the power derating curve.

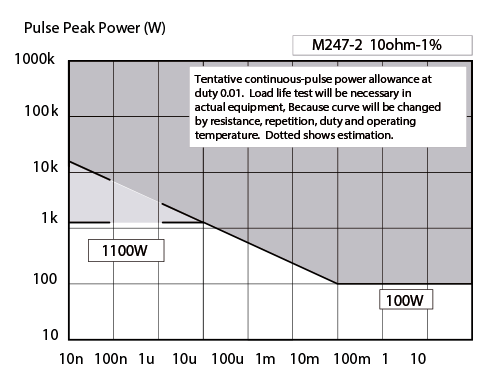

Pulsed operation

Power resistors are used as protection for electronics when high currents have to be absorbed for a short time to protect other components from overload. This can happen, for example, when switching large consumers on and off or in the event of a lightning strike. Power resistors are particularly suitable for these applications with high pulse loads. One example is the use in defibrillators. In a short period of time they release a high amount of energy which can be absorbed by power resistors specified for pulsed operation without any problems for this pulse time. For suitable models, see the data sheet for pulsed operation. Depending on the values for resistance, pulse repetition rate and operating temperature, these values will change, so graphics should be read with caution.

Material technologies of power resistors

Metal wire or metal film technology is particularly common as technologies for power resistors. The two technologies differ fundamentally in the construction of the resistor element and in the materials used, as well as the resulting properties.

Wirewound resistors

Wirewound resistors are manufactured by winding a wire around a carrier core. Precision wirewound resistors are characterized by a particularly high ESD resistance, low noise, and a low temperature coefficient. Due to the winding, however, these components have non-negligible values for inductance and capacitance, which can lead to problems in high-frequency applications. There are different methods of winding these components, which have different advantages and disadvantages depending on the method. See our guide to wirewound resistors. However, wirewound resistors achieve a comparatively better long-term stability and temperature stability than metal film resistors and can be supplied with certain customer-specific resistance values by adapting the winding.

Metal film / Thin film resistors

Metal film resistors have an advantage especially in high frequency applications, because they have very low values for inductance and capacitance. For the production of a metal film resistor numerous processes are used. On a ceramic substrate there is a deposited metal layer of small thickness (the thin film). This layer has a high resistance on a comparatively small area. The thickness of the layer is varied depending on the desired resistance value. Basically, thin-film resistors have a pronounced aging behaviour, since the thin film is susceptible to oxidation and self-etching. For precision components the layer is therefore artificially pre-aged.

Kelvin connection - Four-wire measurement

In addition to the two standard connections, some models of power resistors offer additional outputs as an option, which enable 4-pole Kelvin measurement. If the resistance value of the power resistor is tiny, the connection resistors (and/or other resistors in the line) may be similar in size to the power resistor itself. In this case the falling voltage at the power resistor, and thus the power consumed by the power resistor itself, can no longer be directly monitored over the entire voltage drop at the supply and discharge lines.

The two additional connections enable the direct measurement of the voltage drop at the resistor via a further measuring device. Thus, the current is calculable because the resistance is known and additionally the power at the power resistor is calculable. The system can then be monitored during operation.

Power resistors are highly resilient and designed for high temperature ranges. They resist high voltage and power values with high precision and narrow tolerances. Depending on the resistive element, they exhibit excellent pulse behaviour and low current noise with high reliability. In addition, the optimally designed housings of the heat dissipating resistors open up a wide range of applications.

Our portfolio includes performance values for precision applications. Almost any resistance value can be realized within the scope of technical possibilities. For example, special processes allow us to produce resistors with very low inductance and to adapt the position and pitch of the terminals to suit your application.

MEGATRON is your specialist for the optimal "design in" and your partner for assured quality products. With high delivery reliability, we focus on long-term partnerships and accompany you throughout the entire life cycle of your application; even with relatively small quantities.

EN

EN DE

DE ES

ES FR

FR PT

PT IT

IT