Typical applications:

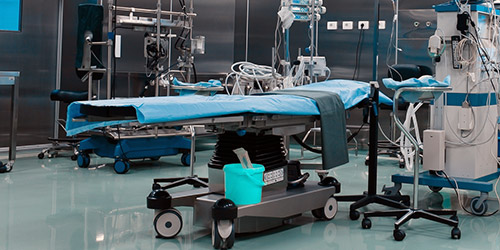

- Joysticks for fine positioning of samples in analysers and medical equipment, control of patient tables.

- Encoders for fine positioning feedback, e.g. in operating tables and patient couches

- Precision potentiometers as feedback elements for servo arms in surgical microscopes

- Panel encoders for menu control of anaesthesia equipment or in emergency medical equipment

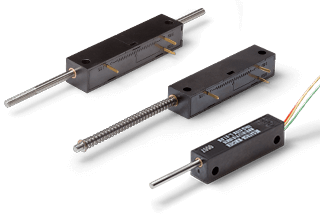

Optical encoder MOM18

Provides reliable and accurate feedback on the height of operating tables

- Convenient and cost-effective connector reduces overall assembly costs

- Increased dielectric strength - to be on the safe side

Operating tables are adjusted on demand. This means that the design of the application must allow for quick, easy and smooth height adjustment. In the operating theatre, even a few millimetres can be decisive for the success of an operation. The compact optoelectronic encoder in the MEGATRON MOM18 series meets this requirement by using an optical angle sensor to monitor the height of the operating table. The higher level of dielectric strength required for product approval is built into the unit during production. We have also designed a bespoke, convenient connector for low-cost assembly of the optical encoder. The complete product thus ensures reliable feedback of table height.

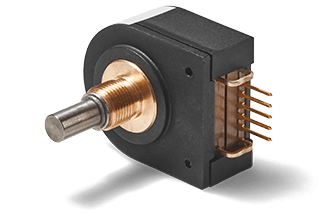

Haptically optimized panel encoder

Panel encoder MRB controls the dosage administered by anaesthesia machines

- Meets safety requirements for reliable operation and fire protection

- Custom shaft length and flattened tip for best-fit, cost-effective installation

The dose to be administered by anaesthesia machines is generally configured manually. These controls must therefore be highly accurate and provide reliable operation. As an additional precaution, the setting can only be changed when the knob is pushed down. In addition, to meet fire safety requirements, the encoder bearing is lubricated with a special non-flammable, inert industrial grease. The incremental encoders of the MEGATRON MRB series are ideally suited to this application. They can only be turned when the knob is pressed down. The necessary grease has been introduced into the bearing, and an additional washer prevents cleaning agents from penetrating into the interior of the encoder. Special attention was also paid to the assembly of the control knob: The length of the shaft of the encoder had to be adjusted by flattening the tip so that the knob could be fitted accurately and comfortably inside the control panel. The product-specific modifications ensure that the anaesthesia machine is controlled accurately and reliably.

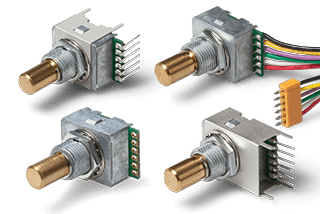

SPM panel encoder

Highly reliable, sensitive encoder for manual input in medical devices

- Special rotational resistance for highly sensitive, precise and accurate manual adjustment

Manual adjustments in medical devices must be precise and reliable. With the rotary or incremental encoders of the MEGATRON SPM series, we have successfully implemented the requirements of many customers: When turning the knob, the user notices a defined rotation inhibition, which enables simple, comfortable and precise adjustment. In highly sensitive applications, the encoders must be fail-safe. This is achieved with redundant versions, e.g. in duplicate with different numbers of pulses.

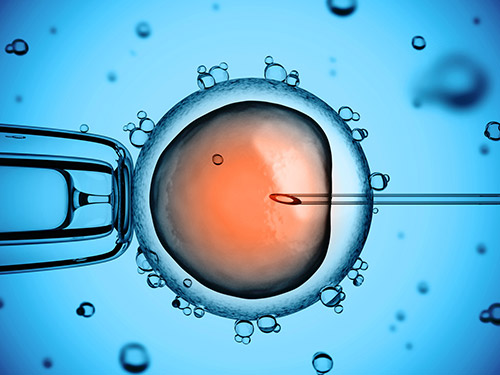

High-precision joystick TRY100

Optimized for assisted fertilisation

- High precision sensor programming

- Customized joystick grip and mechanical characteristics

- Implementation of custom design specifications to match corporate design

Joysticks used in this medical field have to be extremely precise and easy to use. Considering that hand movements with the joystick result in tiny movements in the micrometre range, the electronic and mechanical components must be orchestrated with exceptional precision. The customer application is therefore based on a TRY100 series joystick. We optimized the signal generated to control the joystick and adapted the tactile characteristics to the customer's requirements. We also fully implemented all optical design specifications. The resulting specialized finger joystick, with its high-precision Hall-effect sensor programming, mechanical customization and special tactile characteristics, contributes greatly to achieving the best possible fertilization results.

Optimized joystick grip TRY100

Patient beds for refractive laser eye surgery

- Optimized joystick grip with integrated button ensures intuitive joystick control

- Customized cable characteristics and termination results in reduced assembly costs

Doctors use all their skills and knowledge to provide the best possible patient care. In order to focus their full attention on the surgical procedure, mid-operation adjustments to the patient bed must be completely intuitive and easy. To achieve this goal, we have adapted the ergonomic handle of the TRY100 series joystick to meet these requirements and integrated an additional joystick button for confirmation. Serviceability was also taken into account: The ready-to-install joystick connector significantly reduces service and reassembly costs in the event of a repair. Sometimes it's the small, clever details that make people's jobs easier.

EN

EN DE

DE ES

ES FR

FR PT

PT IT

IT