Product description: Hall effect multi-turn rotary encoder HSM22M

True-Power-On means that any change in angle is detected even during a power failure, and the angle is accurately reproduced as an analogue signal when power is restored.

The contactless sensor technology works on the basis of modern gradient-based magnetic field evaluation in processor-supported circuit design. This makes the multiturn encoder largely immune to external magnetic fields or changing ambient temperatures. In combination with the precision mechanics, the encoder shows its additional strength compared to magnetoresistive methods. The latter can have weaknesses in voltage-free measured value acquisition.

Another feature of the multi-turn sensor is the signal plateaus at the beginning and end of the range, which prevent sudden signal changes. The electrically effective rotation range of the encoder is 3600° ex works. On request, the HSM22M can be factory-programmed with an electrically effective angle of rotation of 360° ≤ α ≤ 3600° to suit the application. The encoder is available for supply voltages of 5 V/DC, 12 V/DC and 24 V/DC and with voltage and current output.

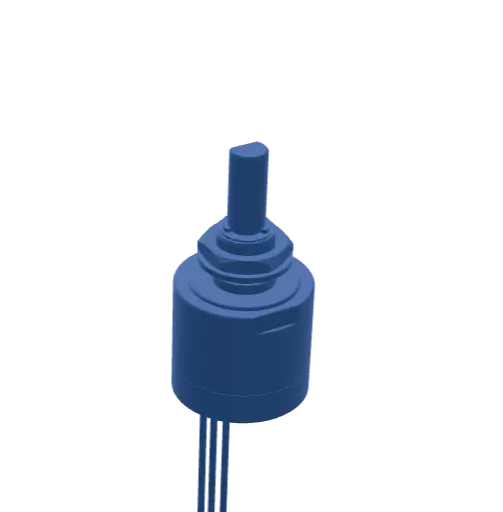

The redundant electronics contains a processor with two separate processor cores, supplied by two independent supply voltages and galvanically isolated signal outputs (6 wires). On request, the redundant electronics can also be ordered with a common power supply and ground (4 electrical connections). The electrical connection consists of single strands with a length of 18 cm.

The encoder housing and precision mechanics are made of metal. The electronics are fully encapsulated in a plastic carrier for optimum protection. The Ø6 mm stainless steel shaft is flattened. The metal sleeve bearing has a life of at least 20 million shaft revolutions. A continuous shaft speed of up to 400 rpm is permitted.

The HSM22M is the first choice when optimum reliability is required. Typical applications include precise position sensing of winches and actuators. MEGATRON can customize the HSM22M with special shaft geometry, electrical connections and user-defined output signals.

EN

EN DE

DE ES

ES FR

FR PT

PT IT

IT