With their tested hygienic design and salt-mist resistant metal housing, the new FHx58 encoders are convincing in the food industry, pharmaceuticals and offshore applications. They meet the highest demands for precision, lifespan and stability. MEGATRON offers the encoders as incremental encoders or absolute encoders with CANbus/SSI interface and energy harvesting technology.

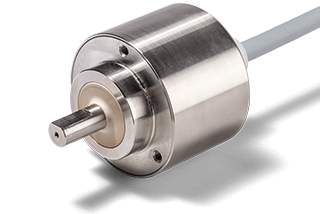

FHx58 encoders are among the most robust angle sensors in their size class thanks to their special housing design. This is ensured by the surface-treated body made of solid stainless steel in combination with materials such as PTFE and TPE. The encoder's dead-space-free shaft sealing element and encapsulated housing design enable high-pressure and steam-jet cleaning of the encoders (IP69K). Due to their insensitivity to cleaning and hygienic agents, the encoders are mainly used in applications with high hygiene standards (EHEDG-approved hygienic design). Its special design also allows the FHx58 to be operated permanently in salty atmospheres (salt-mist resistant according to DIN EN60068-2-11) and to be cleaned with fluids containing acids or alkalis (ECOLAB-certified design). Furthermore, the encoders are equipped with high-quality ball bearings. They allow the shaft to be continuously loaded with up to 100 N. FHx58 encoders are designed for a lifespan of at least 20 years and the electronics have a Mean Time to Failure (MTTF) of 1000 years.

The signal processing of the HTx58 encoders is digital and is based on magnetic, gradient-based or optoelectronic measured value recording. As absolute encoders, the encoders offer up to 16 bit single-turn resolution and up to 43 bit multi-turn resolution. The digital communication interfaces CANopen, SAE J1939 and SSI ensure reliable digital transmission of the measured values. In addition, they guarantee smooth integration and monitoring of the encoder in the application. In the version with battery- and gearless energy harvesting technology, the encoders record the number of revolutions made even in a de-energized state.

As an incremental encoder with optoelectronic scanning, the electronics offer up to 25,000 ppr and are designed with many output options - such as TTL, HTL (also RS422-compatible), each single (A, B, Z) or differential (A, A/, B, B/, Z, Z/). In addition, the encoder has an electronic early warning system (EWS) that signals an impending error approx. 1000 h before the encoder fails.

The electrical connection of the FHx58 encoders is made via a special shielded 2 m round cable made of TPE, which is permanently connected to the encoder. FHx58 encoders are manufactured in Germany and cover a very wide range of applications thanks to the variety of options.

EN

EN DE

DE ES

ES FR

FR PT

PT IT

IT